|

Contact our experts at:

1-800-741-1258

or

sales@loadingdocksupply.com

|

DOCK BUMPER SELECTION GUIDE

For the most comprehensive dock protection, a combination of vertical and horizontal bumpers, provides the greatest protection for both facilities and tractor trailers. For example, an 8’ wide bay door receiving trucks at a straight approach are best protected by 24” high bumpers on either side and a standard 10” high bumper in the center. This allows a variety of trailer heights to be accommodated without the risk of trailers coming in below the 10” bumper centered in the opening. For refrigerated docks, extra length dock bumpers work as a vital component of the door seal effectively controlling air flow from the base of the door when used in conjunction with a dock seal. Overlapping angles are available for use on docks where a continuous bumper is undesirable.

|

- Use combinations of bumpers for optimal protection

- All bumpers have customizable widths

- When installed properly all bumpers are maintenance free

- Always verify the types of trucks being received before planning a loading dock

Dock Bumper Heights

Dock bumper heights are relative to the recycled tire pads used for manufacturing, typically these come in 6”, 10”, & 12” Heights. While the industry standard dock bumpers are built to this, greater heights are effectively achieved by stacking pads on top of each other. This allows for the production of 20”, 24”, & 36” high bumpers.

For best results always choose bumper heights which will best accommodate your traffic and facility. 6”dock bumpers are traditionally used on docks where a lip protrudes from the wall and has a face of 10” or less. 10” dock bumpers are the most widely used for docks where trucks come in at approximately equal heights or when only standard size trucks are received. The 12” Dock Bumper, our tallest single pad size, is a heavy duty product constructed with three pins through the center of rubber slats rather than the two pins used for 6” & 10” bumpers.

| |

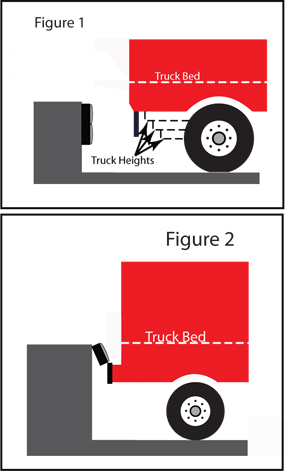

| Always remember the combination of 20", 24", or 36" vertical bumpers, with standard sizes, provides extended depth protection for varying truck heights; (Fig. 1) or the lower steel members of trailer bodies. Consider these for docks that accommodate panel and pebble trucks as well as over the road trailers.

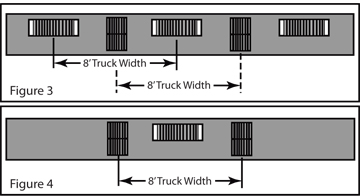

Vertical units with steel faces are particularly applicable with truck leveling devices that raise the entire truck to dock level. The Combination of horizontal units with, (Figs. 3 & 4), vertical units prevents a loaded trailer from dislodging shorter bumpers as the truck bed rises during unloading (Fig. 2).

| |

Dock bumper thickness

Dock bumper thickness is the second most important component besides placement of the bumpers. The determinant of bumper thickness is either the slope of dock approach or various obstructions protruding from the dock face. The typical projection for a dock bumper is 4.5”, this is intended for a dock with a level approach & no obstructions around the door way. Bumpers should always place the top of a trailer a minimum of 4” between the tallest trailers top and wall. For approaches sloping down towards the dock greater thicknesses are required.

To measure your slope, attach a string to the floor of your dock and pace 50’ away following the approach of the trailer. Using a line level determine the line drop at 50’. Divide this number by 600 and you will have your percentage of slope. For every percent of slope figure 1” of additional projection on a standard 4.5” bumper projection. For example, a 5% slop requires a 10” bumper projection.

BUMPER INSTALLATION

Install bumpers (Fig 10) 1" to 2" below dock level. Use 3/4" or 5/8" lag bolts or sleeve anchors; minimum length 3" and use corresponding shield if required. Use 3/4" "J" bolts with a minimum length of 8" with 1 1/4" projection.

Dock Bumper For Open Docks

Open docks without predetermined docking positions, are best suited to a combination of several bumper sizes and placements (Fig.3). When using 36” horizontal dock bumpers maximum spacing should be 24” between units with a minimum of 5” on centers (Fig.6).

- If trucks are approaching at an angle a continuous bumper or overlapping angles should be used to limit the chance of a trailer corner coming in contact with the wall.

- Typically when continuous protection is necessary overlapping angles can provided economical benefits by reducing the number of holes drilled and the number of materials used for installation (Fig. 5).

- Overlapping reduces the spacing between each bumper to 4", and is applicable to any laminated bumper model.

- Overlapping angles on adjacent bumpers increases the protected area.

- Special-length bumpers to fill out dock spaces are also available.

- For open docks or wide bays, extra-length, one-piece dock bumpers can also be used for maximum coverage and appearance (Fig. 7)

Dock Bumper For 8', 9' or 10' Bays

For 8', 9', or 10' bays a variety of combinations exist. Loading Dock Supply recommends a combination of standard and vertical bumper designs (Fig 3 & 4) for dock protection.

Dock bumper For Refrigerated Doors (with or without dock shelters)

Refrigerated doors generally require a, solid one-piece construction, bumper for a complete seal around the truck and dock (Fig. 7). The same applies to doors sealed to maintain temperatures (Similiar results can also be acheived with overlapping angles see (Fig .5). With shelters, the rubber surface of the bumper must extend under the vertical members of the Shelter pad to complete the seal.

Effectively use your dock plate by centering a 36” bumper below the door opening, this allows for simple plate insertion even when a truck is already docked. Allow space for your plate legs and mount vertical bumpers at the desired distances on either side.

When using 14” hole centers, height should be a minimum of 12”. Most boards adequately handle 4.5” & 6” bumper projections without impairing lip penetration into truck opening. Fig 8 shows damage from "short spacing". Fig 9 shows "lateral safety zone" impact absorption advantage provided by longer bumpers.

Disclaimer

Every effort has been made to accurately describe our products and to define their general usage. Determination of the suitability of any product and any application contemplated by the Buyer is the sole responsibility of the Buyer or User. In the event of improper product selection by the Buyer, Loading Dock Supply makes no warranty or guarantee of results to be obtained since use and application by the Buyer are beyond our control. Our goal is to quote you 1.) The "right" bumpers for the application at hand. 2.) To provide customer service that will "save" you money. 3.) To have "satisfied" customers need for all their Loading Dock Supplies.

|

|

Ask about our

Quantity Discounts

Monday - Friday

9 am - 5 pm EST

Call the Experts!

1-800-741-1258

|

Loading Dock Bumpers In All Styles and Sizes

Dock Bumper Supply is your Loading Dock Supply

| Contact Information |

|

|

|

Customer Service |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Custom Quote |

|

|

|

|

About Us |

|

|

|

|

|

|

|

|

|

|

| Loading Dock Supply, LLC |

|

|

|

|

| 5405 Keating Rd NW |

|

|

|

|

| Olympia, WA 98502 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| (Toll Free): 1-800-741-1258 |

|

|

|

|

| Fax: 1-866-709-2802 |

|

|

|

|

Serving AL, AK, AS, AZ, AR, CA, CO, CT, DE, DC, FL, GA, ID, IL IN, IA, KS, KY, LA, ME, MH, MD, MA, MI, MN, MS, MO, MT, NE, NV, NH, NJ, NM, NY, NC, ND, OH, OK, OR, PA, RI, SC, SD, TN, TX, UT, VT, VA, WA, WV, WI, WY

United States of America

|

|